What machine is needed to make square ventilation ducts?

Jul 17, 2024

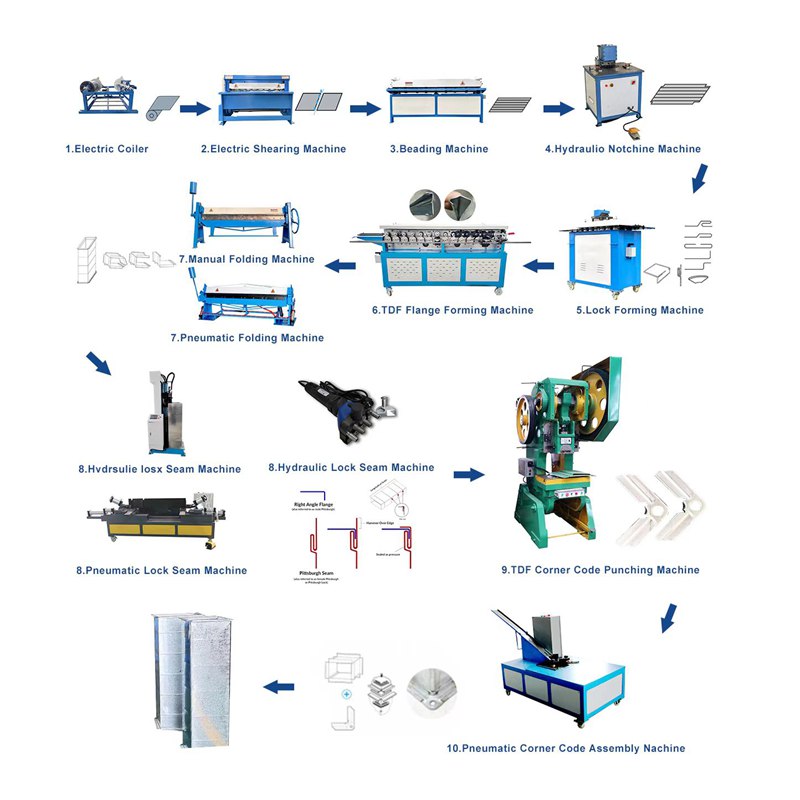

Making square ventilation ducts requires a series of professional machine to ensure production efficiency and product quality. Here are some of the main pieces of machine and their functions:

1. Fully automatic air duct production line: This is the core machine for making square ventilation ducts. It can automatically complete multiple production steps of air ducts, such as cutting, forming, folding, seaming, etc. Fully automatic air duct production lines usually consist of multiple systems, which can process air ducts of different sizes, shapes and specifications according to needs, and can adjust the production speed to improve production efficiency.

2.CNC plasma cutting machine: used to accurately cut the required shape and size from metal plates, which is an important pre-process for making square ventilation ducts. CNC plasma cutting machine has the characteristics of high precision and high efficiency, which can greatly improve the accuracy and efficiency of cutting.

3.Hydraulic racks (for storing and transporting metal sheets or coils)

4.Electric shearing machine: Uses a press to cut metal plates. It is one of the indispensable equipment in the process of making square ventilation ducts. The electric shearing machine has the characteristics of fast cutting speed and high precision, and can meet the cutting needs of metal plates of different specifications and thicknesses.

5.The air Duct Beading Machine is a mechanical device used to connect air ducts. Its main function is to press the metal plates at the air duct connections into a specific shape (such as flat or reinforced rib shape), thereby increasing the firmness of the connection. and sealing.

6.Hydraulic angle shearing machine is a piece of machine used for shearing and processing metal sheets. It can efficiently and accurately complete shearing work at various angles. It is widely used in sign making, road warning signs, stainless steel plate angle cutting, and aluminum plate shearing. and many other fields.

7.Pittsburgh Lock Forming Machine: Presses sheet metal into special shapes so that the parts can be locked together to form a solid component. In the production of square ventilation ducts, the Pittsburgh Lock Forming Machine is used for the connecting part of the air duct to ensure that the connection of the air duct is firm and reliable.

8.Flange forming machine: used to make flanges, which are important components for connecting pipes and can quickly connect and disassemble pipe parts. The flange forming machine punches metal plates into flange shapes and provides necessary accessories for the connection of air ducts.

9.Folding machine: Used to bend metal plates into the required shape, especially the corners of square ventilation ducts. The folding machine can ensure that the corners of the air ducts are flat and have good sealing properties.

10.The air duct seaming machine is a mechanical device specially used for seaming (that is, connecting and sealing two or more parts of the air duct) air ducts (such as ventilation ducts, air conditioning ducts, etc.).

11.The corner code production line is an automated production line specially used to produce corner codes (connectors). As connectors, corner codes are widely used in the fields of construction, industry and furniture manufacturing, especially playing an important role in the construction of aluminum profile frames.

12.The Corner Code Assembly Machine is a mechanical machine specially used to install corner codes (a type of connector commonly used in construction, ventilation ducts, etc.).

It should be noted that the above machine is not all the machine for making square ventilation ducts. The specific machine needs to be selected based on factors such as production scale, product specifications, and production technology. At the same time, when using these machine, it is necessary to strictly abide by operating procedures and safety regulations to ensure safety and stability during the production process.

In addition, with the development of science and technology, some new automation machine and technologies are also emerging, such as laser cutting machines, automated welding robots, etc. These machine and technologies can further improve the production efficiency and product quality of square ventilation ducts. Therefore, when selecting machine, the introduction of these new machine and technologies can also be considered.