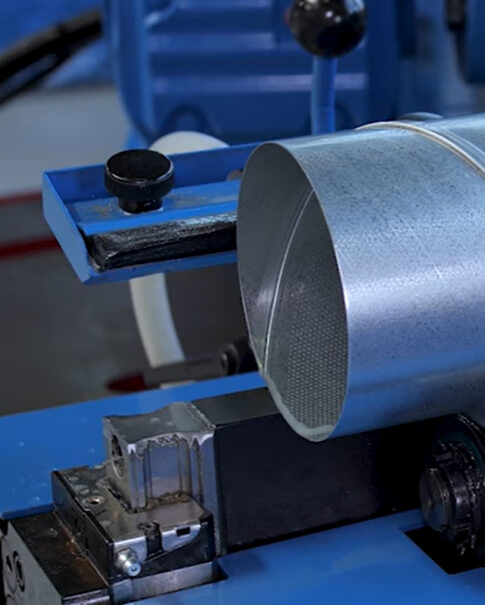

Introduction to the Rotary Beading Machine

Aug 27, 2024

The Rotary Beading Machine is an important equipment in the production of round air ducts. It is mainly divided into two types: manual Rotary Beading Machine and electric Rotary Beading Machine. The following is a detailed introduction to the Rotary Beading Machine:

1. Basic overview

Function: The Rotary Beading Machine is mainly used for beading and connecting round pipes, and can produce different shapes through different pressing wheels to meet the different needs of customers. Its functions mainly include bead pressing and flanging.

Application: It is widely used in the fields of air duct production, hardware lighting, decoration engineering and other fields.

2. Classification and characteristics

Manual Rotary Beading Machine

Features: The operation is relatively simple, but the efficiency is low, suitable for small-scale production or special occasions.

Example: Manual Rotary Beading Machine HCY 18, which can be used for bead line drawing, metal forming, automobile shaping and crimping, etc., and can be used with a bracket.

Electric Rotary Beading Machine

Features: High degree of automation, high production efficiency, able to meet the needs of large-scale production.

Diverse functions: It not only has the functions of bead pressing and flanging, but can also be processed into other shapes according to needs.

Examples: Electric Rotary Beading Machine LX-15, small tinplate galvanized sheet flanging machine;HCY-12 electric Rotary Beading Machine, standard mold, foot control, easy to operate.

3. Technical parameters

The technical parameters of electric Rotary Beading Machines vary by model and manufacturer, but usually include motor power, production speed, wire diameter range, reel head specifications, etc. For example, a certain model of electric thread reeling machine may have the following technical parameters:

Motor power: 4KW

Production speed: multi-stage variable speed, such as one stage 5.5m/min, two stages 8.5m/min, three stages 14m/min, four stages 24m/min

Wire diameter range: φ0.5mm-φ6.0mm

Reel head specifications: φ114mm

4. Market situation

There are currently many brands and models of Rotary Beading Machines on the market, with prices ranging from a few hundred yuan to tens of thousands of yuan. Different brands and models of reeling machines have differences in functions, performance, prices, etc. Users can choose the appropriate equipment according to their own needs.

5. Use and maintenance

Usage: When using the Rotary Beading Machine, the operating procedures should be strictly followed to ensure the safe and stable operation of the equipment.

Maintenance: Regularly perform maintenance on the Rotary Beading Machine, such as cleaning, lubrication, inspection, etc., to extend the service life of the equipment.

6. Development Trend

With the continuous development of industrial automation, electric Rotary Beading Machines will continue to improve in terms of function, performance, and intelligence. In the future, electric reeling machines will be more adaptable to large-scale, high-efficiency production needs and become one of the important equipment in fields such as circular duct production.

In summary, as an important equipment in the production of circular ducts, the Rotary Beading Machine has broad application prospects and development space. When selecting and using a Rotary Beading Machine, users should fully consider their own needs and pay attention to the technical parameters, performance, price and other information of the equipment.