Corrugated Duct Forming Machine is designed for the efficient production of corrugated ducts used in various applications, including HVAC systems and ventilation. It features advanced technology for precise shaping and forming, ensuring high-quality duct performance. This machine enhances productivity, reduces labor costs, and delivers consistent results, making it an essential tool for manufacturers in the ductwork industry.

HS 코드 :

8455229090최소 주문하다 :

One Set제조 시간 :

Almost IN STOCK지불 조건 :

TT,LC,West Union etc포장 방법 :

Exporting wooden box품질 보증 기간 :

18 month from B 'L issued date연간 생산 능력 :

200 sets machines고객 디자인 또는 OEM :

AcceptedHVAC Corrugated Duct Forming Machine

I. Corrugated Duct Forming Machine's Features:

Spiral tube machine is used for producing HVAC round duct. Spiral duct is made of metal strip rolled into a spiral bite wall of the thin tube, round, no welding, no leakage. The spiral tube machines produced by HCY company have high yield and stable pipe diameter, and good bite, good sealing, long-term innovation.1.Spiral tube machine with patented mold which has its own patent and easy to adjust, save the metal strip.

.1. Materials: galvanized steel

2. Galvanized sheet width:78mm

3. Thickness range: 0.2-0.6mm

4. Number of corrugates: 4 PCS

5. Diameter range:40-150mm

6. Maximum output: 20m/min

7. Extruder center height: 1100mm

8. Power: 20KW

9. Dimension:2400x1900x2000mm

10. Weight:1360KGS

II. Technical Parameters

1. Host machine

A. Host machine

1) Variable frequency motor: 15KW

2) Variable frequency speed regulation device (sine): 15KW

B. Reducer

1) Box material: HT200

2) Gear type: Helical gear

3) Gear material: 20CrMnTi

4) Gear surface heat treatment: Tooth surface carburizing, grinding treatment

C. Drive motor

1) Model: YE3-160L-4

2) Type: Variable frequency motor

3) Power: 15KW

4) Motor controller: Variable frequency speed regulation (sine)

5) Maximum speed: 1470r/min

D. Control electrical appliances

1) Contactor: Siemens

2) Control screen: Siemens

3) PLC: Siemens

E. Cutting machine

1) Motor power: 2.2KW

2) Motor model: HM71/80-03-2.2-F

3) Maximum speed: 3000r/min

4) Cutting method: Saw blade

5) Starting mode: travel switch

F. Auxiliary motor (It is necessary to equip it when the steel strip is very thick)

1) Controller: Kumark

2) Motor power: 2.2KW

3) Motor model: TYPE YVP-112M-6

2. Molds

1)Material: High wear-resistant mold steel

2)Process and heat treatment: Normalizing, tempering, quenching and tempering, quenching (nitriding)

3. Unloading rack

1) Length: 12 meters (4 meters X 3PCS)

2) Mode: Pneumatic

4. Loading rack

1)Inner diameter of steel coil (changeable): 250mm/500mm

5. Spot welding machine

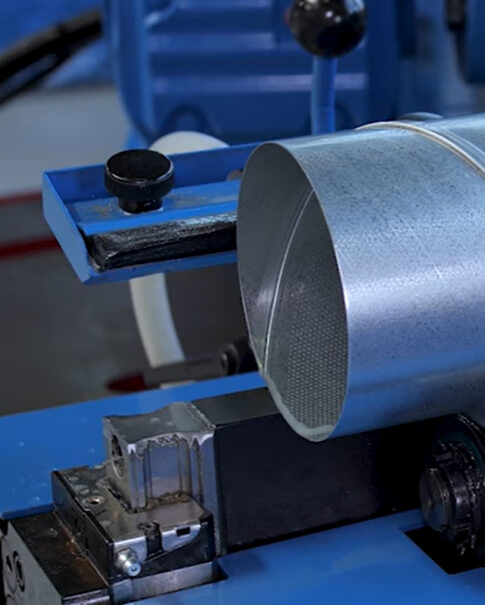

III. Real Photos:

IV. Quality Certifications:

V. RFQ:

1. Are you manufacturer or trading company?

We are manufacturer.

2. What shall we do if don't know how to operate your machine?

We can dispatch our engineers to your country and you can also send your engineers to our factory for learning operation. Besides, there are detailed installation and operating instructions attached, it is very simple. We have telephone and email support at 24 hours per day.

3.How about your machine quality?

HCY company is a mature brand in CHINA,through our 15 years research in technology,our design including structure and detailed security and precision has enhanced greatly,and can match all the CE standard or more strict standard.Our machines distribute worldwide to about 50 countries where there are metal plate industry And where there are our machines,there are good reputation and terminal user satisfaction.

4. What are your payment terms?

We support T/T, L/C, D/P, D/A, Western Union and so on. TT, 30% in advance, 70% balance before the shipment.

5.Can we be your agent?

Yes,we are looking for Global agent we will help agent improve the market ,and supply all the service like machine technical

problem or other after-sales problem, meanwhile ,you can get big discount and commission.

6.Do you accept customer Logo and customized ?

we accept kinds of customized ,including logo and machine .

핫 태그 :